10-Ton Electric Hoist Distribution Box Installation and Fault Repair Case Analysis

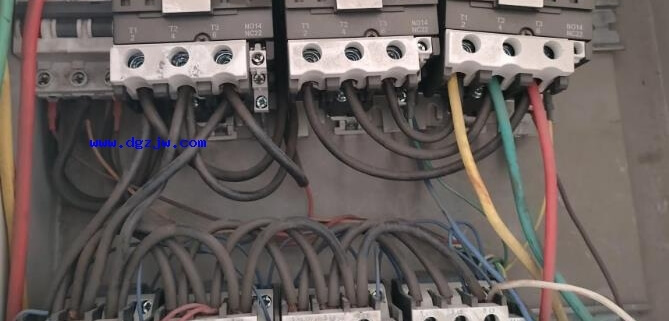

This is a 10-ton electric hoist distribution box, installed by a professional master. I found two wrong places from it. How many can you find?

A 10-ton electric hoist was repaired today, which was damaged by the worker. The fault was caused by the pull-up wire. Motor On the upper, the worker didn’t pay attention to the scratching of the cable. He started the remote control and pressed no response. It was initially determined that the cable had grounding or short-circuiting, which resulted in the distribution box. breaker Tripped.

There is a situation that is very troublesome now. The gourd is broken in the middle of the car. If you pull the trot motor on the wire, you can use it to get the trot motor on the wire.power supply If the wire is broken, it is very troublesome to go up and repair it. You can only use a lift truck, and the lift truck cannot be pulled over. The workshop is covered with steel, and it is difficult for forklifts to leave.

There is also an optimistic situation, that is, there is a main hook motor power cord and a heavy hammer limit cord inside the pull wire. If they are grounded or short-circuited, just remove the wire and send the power to the starting trot motor and the hoist to the maintenance platform for maintenance, which saves time and time.

I took the tool and went to the Tianche distribution box. I opened the door circuit breaker and tripped. I first used a meter to measure the trot motor wire, but it was not grounded. I measured the main hook motor wire, and it turned out to be grounded. It seemed that the cable was damaged. I was looking for the rising limit wire and I was measuring it, but I didn’t find it.

Logically speaking, the rising yellow control line should be connected to the limit line, and the back line should be connected to the Contactor I searched for a while but couldn’t find it, and finally I pulled the control line a few times before I found out how to connect it.

This is the first time I have seen this connection method. I am really convinced. The common wire of the contactor should be connected in parallel to A1 to connect to the power supply. As a result, he picked up a power supply from the descending contactor into coil A2. After coming out of A2, a control wire was connected to the uplift limit switch. When the switch was out, it was connected to the uplift contactor coil.

I don’t know which master taught me this way. At the beginning, I was confused. The limits were all connected to the control wires, and I had never seen them connected to the common wires. There was no control switch in the distribution box, and the control power supply was connected to the 3P circuit breaker. I couldn’t try the contactor alone.

Finally, send the power supply, open the hoist to the platform, and connect the damaged cables, and repair this time.

Leave a Reply

Want to join the discussion?Feel free to contribute!